GOM Offshore Industry Faces Infrastructure Challenge

by Ben Casselman

The Wall Street Journal,

Wednesday, December 15, 2010

On June 10, 1947, Stanolind Oil & Gas Co. won an auction for the right to drill for oil on a plot seven miles off the Louisiana coast. The company built a spindly steel platform and drilled a well in shallow waters. It struck oil, and in 1950, Stanolind sold its first Louisiana sweet crude for $2.67 a barrel.

More than 60 years later, the West Cameron 45-A platform is, according to government records, the oldest functioning platform in federal waters in the Gulf of Mexico. One of more than 100 structures built in the 1940s and 1950s still in operation, the platform has survived seven Category 2 hurricanes and a major fire.

The platform's age may have taken a toll, however.

On Dec. 4, 2009, a severely corroded pipe connecting the structure to a high-pressure gas well gave way during routine maintenance, releasing explosive natural gas into the air. Unlike most modern platforms, this one had no remote shut-off switch. Emergency valves that should have cut off the flow of gas automatically didn't close properly -- in part, a subsequent investigation found, because a control panel was caked in bird droppings. Workers who had fled by boat to a nearby platform were finally able to shut down the well.

The deadly explosion of the Deepwater Horizon drilling rig in April set off a fierce battle over deep-sea oil drilling aboard huge, state-of-the art vessels. But that debate has largely ignored what many experts say could be a bigger threat: The troubled state of offshore infrastructure that remains in place long after wells are drilled.

High-tech drilling rigs make up only a small piece of the Gulf's energy infrastructure, a vast network of tens of thousands of fixed wells, hundreds of permanent platforms and thousands of miles of undersea pipelines. This network together accounts for nearly a third of the oil produced in the U.S. and more than 10% of the natural gas.

Much of that infrastructure is decades old. Roughly half of the Gulf's more than 3,000 production platforms are 20 years old or more, and a third date back to the 1970s or earlier, long before the development of modern construction standards. More than half have been operating longer than their designers intended, according to federal regulators.

Older structures are more prone to accidents, especially fires, and more dangerous for workers. According to a Wall Street Journal analysis of federal accident records, platforms that are 20 years old or more accounted for more than 60% of fires and nearly 60% of serious injuries aboard platforms in 2009.

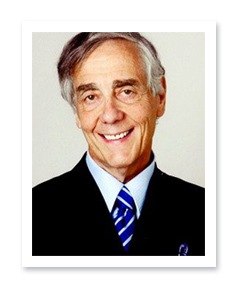

"There is an infrastructure issue confronting the industry," says Charles Swanson, a managing partner with Ernst & Young's Oil & Gas Center in Houston. "We're reaching a point now where we're not going to be able to ignore it any longer."

Platforms are subjected to extreme ocean currents, corrosive salt water and frequent hurricanes. Unlike drilling rigs, which are mobile, platforms can't be brought to shore for repairs. Many are so old or have changed hands so many times, that maintenance records are missing or unreliable. And experts say that maintenance work has often gotten short shrift in an industry focused on new discoveries rather than old, declining fields.

Federal regulators investigated 81 accidents at oil-and-gas facilities in the Gulf of Mexico over the past three years in which equipment failure, the most common cause of accidents, was blamed. In more than a quarter of such cases, according to the Journal analysis, investigators found that age or issues that are often age-related, such as corrosion or rust, contributed to the incident.

The government hasn't conducted any studies specifically on the correlation between platform age and incident rates. But in 1998, a broader study on the industry commissioned by regulators and conducted by researchers at Louisiana State University found what they called a statistically significant correlation: A 1% increase in platform age leads to a 0.3632% increase in the rate of accidents. "Thus, we conclude that older platforms indeed pose a greater risk for accidents," the authors concluded.

Pipelines, too, are often decades old and have a history of spills and leaks due to corrosion. Yet offshore lines are subject to lower inspection standards than those onshore; the vast majority of them aren't designed to hold the internal inspection equipment that looks for corrosion, according to federal regulators.

After last year's pipeline rupture on the 1940s platform, federal investigators found there was "extensive metal loss [and] heavy corrosion build-up on the exterior of the pipe" due to "lack of maintenance."

Stone Energy Corp., which bought the platform in 2001, said in a statement that "the overall age of the equipment and infrastructure was not considered to be a factor in the failure." The company said that "as a general rule, older facilities require more upkeep and maintenance than newer facilities," adding, "We prioritize maintenance . . . with safety of personnel as top priority."

On Tuesday, Stone said it disagreed with investigators' findings and believed its safety devices worked as designed. The company said all its systems met regulators' standards.

Mike Hiner, a deep-water drilling veteran with the engineering firm Hamilton Group, likens old platforms to classic cars, saying they require more maintenance, but can still be run safely. "If it's well maintained, it works," he said.

But industry workers say companies will sometimes cut corners. "Some of the platforms, the catwalks are so rusty you can't get up on them," says Randal Harryman, who worked on platforms in the Gulf for 12 years before retiring when he broke his back on the job in 2005 for reasons unrelated to the age of the platform. "I've been afraid of some of the equipment I've used."

Mr. Harryman, who reached an undisclosed settlement with his employer, says he was mostly stationed on old platforms, many dating to the 1950s and 1960s. He did so-called workover jobs: cleaning out wells, replacing worn-out pipes and plugging up old wells. He says pipes inside wells were routinely so corroded that they broke in two when his crew tried to pull them out.

On a recent Monday in November, a blue-and-white helicopter took off from a small air base here on the southern edge of Louisiana, and flew out over the Gulf. Below, dozens of platforms and structures of all ages and sizes poked out of the water. Rusting tanks sat on wooden docks next to marshland oil wells. Larger, manned platforms stood on steel legs in the shallow water. Farther out, newer platforms floated in deep water.

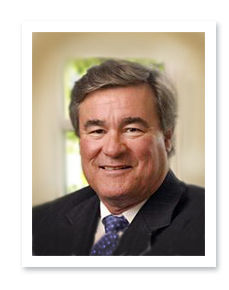

"You can see the entire history of the offshore industry down there," said Paul Bulmahn, chairman and CEO of ATP Oil & Gas, a relatively small oil company in the Gulf.

Mr. Bulmahn was on his way to ATP's Titan, one of the newest platforms. Designed to operate for 40 years, the 64,000-ton Titan is built to withstand powerful hurricanes, as well as swirling ocean currents that can strain the platform's moorings and eat away at its hull. Every three days, remote-controlled submarines with cameras survey the pipes that connect the platform to wells, looking for wear. The 12 polyester ropes that anchor the Titan to the sea floor contain sections that can be removed and inspected.

Many of the platforms Mr. Bulmahn's helicopter flew over en route to the Titan, however, didn't have such rigorous standards in place when they were installed. Few companies have invested in adding advanced monitoring technology to alert them about corrosion or other developing problems. That means the first sign of trouble is often when a valve blows out or a pipe bursts. Such alarms are common. In 2009 there were 133 fires aboard Gulf rigs, 10 oil spills of more than 50 barrels and 17 releases of natural gas that forced facilities to shut down, according to government data. This past April, two weeks before the Deepwater Horizon explosion, an engine-room fire on a shallow-water rig off Louisiana was blamed on a 33-year-old generator that was "prone to failure due to the engine's service life," according to a federal investigation.

In September, the federal government came out with a new policy on aging infrastructure, announcing that it would step up enforcement of existing rules requiring companies to plug dried-up wells and dismantle unused platforms.

The rules, however, don't do anything to address wells that are still in operation -- no matter how old they are.

Nor do they address aging offshore pipelines. While recent onshore pipeline disasters have led to calls for beefed-up regulations onshore, the 25,000 miles of underwater lines that crisscross the Gulf have essentially been ignored. Most of these pipelines are exempt from the kinds of inspections required for pipelines that run through cities and towns.

Yet, ruptured and leaking underwater pipelines have spilled more than 70,000 gallons of oil and other pollutants into the Gulf in more than a dozen incidents in the past three years. A 2007 study found that corrosion is by far the leading cause of offshore pipeline failure.

A 2007 attempt by federal regulators to impose tougher rules for maintaining offshore pipelines was abandoned after opposition from industry groups. In a 232-page rebuttal of the proposed rules, the Offshore Operators Committee argued they were time-consuming, expensive and unnecessary, and questioned the authority of the regulatory agency, the Minerals Management Service, to impose them.

Critics say the failure to adopt new rules on pipelines hints at a broader failure by regulators to force oil companies to maintain their offshore facilities.

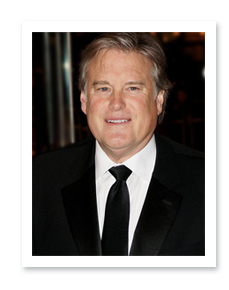

"You're exposing people and you're exposing the environment to unmanaged risk," says Tony Hall, CEO of Welaptega Marine Ltd., a Canada-based company that inspects offshore platforms.

Federal regulators say they are strengthening their standards and toughening enforcement of all offshore operations, including those on aging platforms.

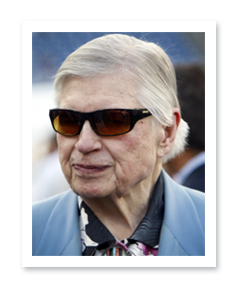

"We are aggressively pursuing substantial reforms of our offshore program, including our inspection program," says Michael Bromwich, director of the renamed Bureau of Ocean Energy Management, Regulation and Enforcement, said in a statement. He says his agency needs more funding to ensure compliance.

The extent of the problem was highlighted after Hurricanes Katrina and Rita barreled through the Gulf of Mexico in 2005, leaving behind a tangle of twisted pipelines, toppled platforms and flooded refineries.

Older structures were particularly hard-hit by the storms. Of the 116 fixed platforms destroyed by Katrina and Rita, half were built in the 1960s or earlier and more than 70% were built before 1980.

The storms served as a wake-up call for the industry. Companies stepped up spending on maintenance and monitoring of older structures, and started removing facilities that were no longer profitable.

But experts generally agree that restoring all the old or outdated U.S. energy infrastructure onshore and off is a multi-trillion-dollar problem. And there are forces pushing companies to keep their facilities going for as long as possible. New technologies have allowed companies to pump more oil out of old fields, extending the lives of the platforms and pipelines that serve them. And high oil prices have led companies to try to continue operating fields that, in the past, would have been considered too old to operate profitably.

Says Sampat Prakash, head of the oil and gas division for consulting firm Deloitte: "High prices give people an incentive to keep at it."

Copyright (c) 2010 Dow Jones & Company, Inc.

![]() Forget unpleasant things that may have happened in the past.

Forget unpleasant things that may have happened in the past.![]() Begin with what you have. Do not wait for conditions to change.

Begin with what you have. Do not wait for conditions to change.![]() Now is the time, here is the place. Begin.

Now is the time, here is the place. Begin.![]() Expect the best and you will have it. Be positive.

Expect the best and you will have it. Be positive.![]() Sow good seeds in the field of your life. Think good thoughts, speak good words and perform good deeds.

Sow good seeds in the field of your life. Think good thoughts, speak good words and perform good deeds.![]() Appreciate every one whom you deal with today and all the days.

Appreciate every one whom you deal with today and all the days.![]() Decide to forgive, and more importantly to forget, a hurt offered to you.

Decide to forgive, and more importantly to forget, a hurt offered to you.![]() Just for today, decide that you will not get angry or lose your temper at all and try to continue.

Just for today, decide that you will not get angry or lose your temper at all and try to continue.![]() Approach any of your elders, bow down to them and thank them for all that they have done for you.

Approach any of your elders, bow down to them and thank them for all that they have done for you.![]() Today, count your blessings! Express your gratitude to God for all the things you take for granted: the air you breathe, the movement of your limbs, your sense of sight and sound.

Today, count your blessings! Express your gratitude to God for all the things you take for granted: the air you breathe, the movement of your limbs, your sense of sight and sound.![]() Maintain your equilibrium and your silence even if you are accused wrongly of anything.

Maintain your equilibrium and your silence even if you are accused wrongly of anything.![]() Do not argue your opinion in any discussion. Listen patiently to the other's view. Then, if necessary you may gently explain yours.

Do not argue your opinion in any discussion. Listen patiently to the other's view. Then, if necessary you may gently explain yours.![]() Begin and end your day with a long and loving chat with God, your Eternal friend and companion.

Begin and end your day with a long and loving chat with God, your Eternal friend and companion.